|

Acicular Ferrite

Acicular ferrite is a microstructure of ferrite in steel that is characterised by needle-shaped crystallites or grains when viewed in two dimensions. The grains, actually three-dimensional in shape, have a thin lenticular shape. This microstructure is advantageous over other microstructures because of its chaotic ordering, which increases toughness. Acicular ferrite is formed in the interior of the original austenitic grains by direct nucleation on the inclusions, resulting in randomly oriented short ferrite needles with a 'basket weave' appearance. Acicular ferrite is also characterised by high angle boundaries between the ferrite grains. This further reduces the chance of cleavage, because these boundaries impede crack propagation. In C-Mn steel weld metals, it is reported that nucleation of various ferrite morphologies is aided by non-metallic inclusion; in particular oxygen-rich inclusions of a certain type and size are associated with the intragranular nucleation of acicul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microstructure

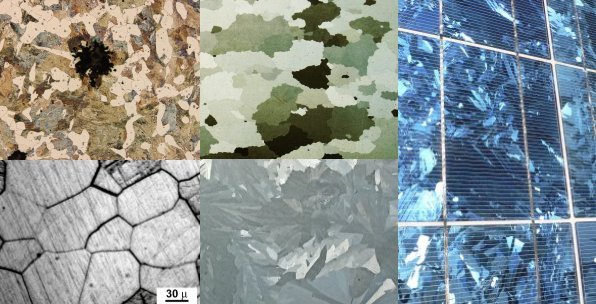

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure’s influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can tak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Allotropes Of Iron

At atmospheric pressure, three allotropic forms of iron exist, depending on temperature: alpha iron (α-Fe), gamma iron (γ-Fe), and delta iron (δ-Fe). At very high pressure, a fourth form exists, called epsilon iron (ε-Fe). Some controversial experimental evidence suggests the existence of a fifth high-pressure form that is stable at very high pressures and temperatures. The phases of iron at atmospheric pressure are important because of the differences in solubility of carbon, forming different types of steel. The high-pressure phases of iron are important as models for the solid parts of planetary cores. The inner core of the Earth is generally assumed to consist essentially of a crystalline iron-nickel alloy with ε structure. The outer core surrounding the solid inner core is believed to be composed of liquid iron mixed with nickel and trace amounts of lighter elements. Standard pressure allotropes Alpha iron (α-Fe) Below 912 °C (1,674 °F), iron has a bod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystallite

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel longulites. Structure The orientation of crystallites can be random with no preferred direction, called random Texture (chemistry), texture, or directed, possibly due to growth and processing conditions. While the structure of a (single crystal, single) crystal is highly ordered and its crystal lattice, lattice is continuous and unbroken, Amorphous solid, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in-between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lenticular (geology)

In geology, a lens or lentil is a body of ore or rock that is thick in the middle and thin at the edges, resembling a convex lens in cross-section. To thin out in all directions is to "lens out", also known as "lensing". The adjectives "lenticular" and "lentiform" are used to describe lens-like formations. Lenticle is a synonym for lentil, but may also refer to a fragment of rock that is lens-shaped. "Lenticule" is used for small lentil. A lentil may also refer a minor unit in a formation of rock, similar to a member but not generally spread out over a large geographical area. In this usage, the lentil thins out towards its edges. Lenticular bedding is a special form of rock interbedded mudrock and cross-laminated rippled sandstone Sandstone is a clastic sedimentary rock composed mainly of sand-sized (0.0625 to 2 mm) silicate grains. Sandstones comprise about 20–25% of all sedimentary rocks. Most sandstone is composed of quartz or feldspar (both silicates) . ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing."Toughness" Brian Larson, editor, 2001–2011, The Collaboration for NDT Education, [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Austenite

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (727 °C); other alloys of steel have different eutectoid temperatures. The austenite allotrope is named after Sir William Chandler Roberts-Austen (1843–1902); it exists at room temperature in some stainless steels due to the presence of nickel stabilizing the austenite at lower temperatures. Allotrope of iron From alpha iron undergoes a phase transition from body-centered cubic (BCC) to the face-centered cubic (FCC) configuration of gamma iron, also called austenite. This is similarly soft and ductile but can dissolve considerably more carbon (as much as 2.03% by mass at ). This gamma form of iron is present in the most commonly used type of stainless steel for making hospital and food-service equipment. Material Austenitizati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Widmanstätten Pattern

Widmanstätten patterns, also known as Thomson structures, are figures of long nickel–iron crystals, found in the octahedrite iron meteorites and some pallasites. They consist of a fine interleaving of kamacite and taenite bands or ribbons called ''lamellae''. Commonly, in gaps between the lamellae, a fine-grained mixture of kamacite and taenite called plessite can be found. Widmanstätten patterns describe features in modern steels, titanium, and zirconium alloys. Discovery In 1808, these figures were observed by Count Alois von Beckh Widmanstätten, the director of the Imperial Porcelain works in Vienna. While flame heating iron meteorites, Widmanstätten noticed color and luster zone differentiation as the various iron alloys oxidized at different rates. He did not publish his findings, claiming them only via oral communication with his colleagues. The discovery was acknowledged by Carl von Schreibers, director of the Vienna Mineral and Zoology Cabinet, who named the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleavage (crystal)

Cleavage, in mineralogy and materials science, is the tendency of crystalline materials to split along definite crystallographic structural planes. These planes of relative weakness are a result of the regular locations of atoms and ions in the crystal, which create smooth repeating surfaces that are visible both in the microscope and to the naked eye. If bonds in certain directions are weaker than others, the crystal will tend to split along the weakly bonded planes. These flat breaks are termed "cleavage."Hurlbut, Cornelius S.; Klein, Cornelis, 1985, '' Manual of Mineralogy'', 20th ed., Wiley, The classic example of cleavage is mica, which cleaves in a single direction along the basal pinacoid, making the layers seem like pages in a book. In fact, mineralogists often refer to "books of mica." Diamond and graphite provide examples of cleavage. Both are composed solely of a single element, carbon. But in diamond, each carbon atom is bonded to four others in a tetrahedral pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bainite

Bainite is a plate-like microstructure that forms in steels at temperatures of 125–550 °C (depending on alloy content). First described by E. S. Davenport and Edgar Bain, it is one of the products that may form when austenite (the face-centered cubic crystal structure of iron) is cooled past a temperature where it is no longer thermodynamically stable with respect to ferrite, cementite, or ferrite and cementite. Davenport and Bain originally described the microstructure as being similar in appearance to tempered martensite. A fine non-lamellar structure, bainite commonly consists of cementite and dislocation-rich ferrite. The large density of dislocations in the ferrite present in bainite, and the fine size of the bainite platelets, makes this ferrite harder than it normally would be. The temperature range for transformation of austenite to bainite (125–550 °C) is between those for pearlite and martensite. In fact, there is no fundamental lower limit to the ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Martensite

Martensite is a very hard form of steel crystalline structure. It is named after German metallurgist Adolf Martens. By analogy the term can also refer to any crystal structure that is formed by diffusionless transformation. Properties Martensite is formed in carbon steels by the rapid cooling (quenching) of the austenite form of iron at such a high rate that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to form cementite (Fe3C). Austenite is gamma-phase iron (γ-Fe), a solid solution of iron and alloying elements. As a result of the quenching, the face-centered cubic austenite transforms to a highly strained body-centered tetragonal form called martensite that is supersaturated with carbon. The shear deformations that result produce a large number of dislocations, which is a primary strengthening mechanism of steels. The highest hardness of a pearlitic steel is 400 Brinell, whereas martensite can achieve 700 Bri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in front of oxygen (32.1% and 30.1%, respectively), forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust. In its metallic state, iron is rare in the Earth's crust, limited mainly to deposition by meteorites. Iron ores, by contrast, are among the most abundant in the Earth's crust, although extracting usable metal from them requires kilns or furnaces capable of reaching or higher, about higher than that required to smelt copper. Humans started to master that process in Eurasia during the 2nd millennium BCE and the use of iron tools and weapons began to displace copper alloys, in some regions, only around 1200 BCE. That event is considered the transition from the Bronze Age to the Iron A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |