|

3D Weaving

Three-dimensional composites use fiber preforms constructed from yarns or tows arranged into complex three-dimensional structures. These can be created from a 3D weaving process, a 3D knitting process, a 3D braiding process, or a 3D lay of short fibers. A resin is applied to the 3D preform to create the composite material. Three-dimensional composites are used in highly engineered and highly technical applications in order to achieve complex mechanical properties. Three-dimensional composites are engineered to react to stresses and strains in ways that are not possible with traditional composite materials composed of single direction tows, or 2D woven composites, sandwich composites or stacked laminate materials. 3D Woven Composites Three dimensional woven fabrics are fabrics that could be formed to near net shape with considerable thickness. There is no need for layering to create a part, because a single fabric provides the full three-dimensional reinforcement. The 3-D woven fabr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses (referred to as "weights"). Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue. Etymology The word yarn comes from Middle English, from the Old English ''gearn'', akin to Old High German ''garn'', "yarn," Dutch "garen," Italian ''chordē'', "string," and Sanskrit ''hira'', "band." History The human production of yarn is known to have existed since the Stone Age and earlier prehistory, with ancient fiber mat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formability

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage). Processes affected by the formability of a material include: rolling, extrusion, forging, rollforming, stamping, and hydroforming. Fracture strain A general parameter that indicates the formability and ductility of a material is the fracture strain which is determined by a uniaxial tensile test (see also fracture toughness). The strain identified by this test is defined by elongation with respect to a reference length. For example, a length of is used for the standardized uniaxial test of flat specimens, pursuant to EN 10002. It is important to note that deformation is homogeneous up to uniform elongation. Strain subsequently localizes until fracture occurs. Fracture strain is not an engineering st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Horn Gear

A braiding machine is a device that interlaces three or more strands of yarn or wire to create a variety of materials, including rope, reinforced hose, covered power cords, and some types of lace. Braiding materials include natural and synthetic yarns, metal wires, leather tapes, and others. Process #Fibers are spun into yarn. #One or more yarns are twisted together to form a strand. #Strands are wound onto bobbins. #Bobbins are mounted on carriers. #Carriers are mounted onto a braiding machine, where the braiding takes place. Horn gear braider In a horn gear braider, bobbins of thread pass one another to the left and right on pseudo-sinusoidal tracks. The bobbins are mounted on spool carriers that are driven by a series of ''horn gears''. A horn gear is a notched disk driven by a spur gear below on the same shaft; bobbins are transferred between notches of adjacent gears. These gears lie below the track plate that the bobbin carriers ride on. The gears must be driven at multipl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Braids2

A braid (also referred to as a plait) is a complex structure or pattern formed by interlacing two or more strands of flexible material such as textile yarns, wire, or hair. The simplest and most common version is a flat, solid, three-stranded structure. More complex patterns can be constructed from an arbitrary number of strands to create a wider range of structures (such as a fishtail braid, a five-stranded braid, rope braid, a French braid and a waterfall braid). The structure is usually long and narrow with each component strand functionally equivalent in zigzagging forward through the overlapping mass of the others. It can be compared with the process of weaving, which usually involves two separate perpendicular groups of strands (warp and weft). Historically, the materials used have depended on the indigenous plants and animals available in the local area. During the Industrial Revolution, mechanized braiding equipment was invented to increase production. The braiding te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Braids

A braid (also referred to as a plait) is a complex structure or pattern formed by interlacing two or more strands of flexible material such as textile yarns, wire, or hair. The simplest and most common version is a flat, solid, three-stranded structure. More complex patterns can be constructed from an arbitrary number of strands to create a wider range of structures (such as a fishtail braid, a five-stranded braid, rope braid, a French braid and a waterfall braid). The structure is usually long and narrow with each component strand functionally equivalent in zigzagging forward through the overlapping mass of the others. It can be compared with the process of weaving, which usually involves two separate perpendicular groups of strands (warp and weft). Historically, the materials used have depended on the indigenous plants and animals available in the local area. During the Industrial Revolution, mechanized braiding equipment was invented to increase production. The braiding te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

I-beam

An I-beam, also known as H-beam (for universal column, UC), w-beam (for "wide flange"), universal beam (UB), rolled steel joist (RSJ), or double-T (especially in Polish language, Polish, Bulgarian language, Bulgarian, Spanish language, Spanish, Italian language, Italian and German language, German), is a beam (structure), beam with an or -shaped cross section (geometry), cross-section. The horizontal elements of the are flanges, and the vertical element is the "web". I-beams are usually made of structural steel and are used in construction and civil engineering. The web resists shear forces, while the flanges resist most of the bending moment experienced by the beam. The Euler–Bernoulli beam equation shows that the I-shaped section is a very efficient form for carrying both bending and shearing (physics), shear loads in the plane of the web. On the other hand, the cross-section has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on naturally occurring resins. Plants secrete resins for their protective benefits in response to injury. The resin protects the plant from insects and pathogens. Resins confound a wide range of herbivores, insects, and pathogens, while the volatile phenolic compounds may attract benefactors such as parasitoids or predators of the herbivores that attack the plant. Composition Most plant resins are composed of terpenes. Specific components are alpha-pinene, beta-pinene, delta-3 carene, and sabinene, the monocyclic terpenes limonene and terpinolene, and smaller amounts of the tricyclic sesquiterpenes, longifolene, caryophyllene, and delta-cadinene. Some resins also contain a high proportion of resin acids. Rosins on the other hand are less ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Porosity

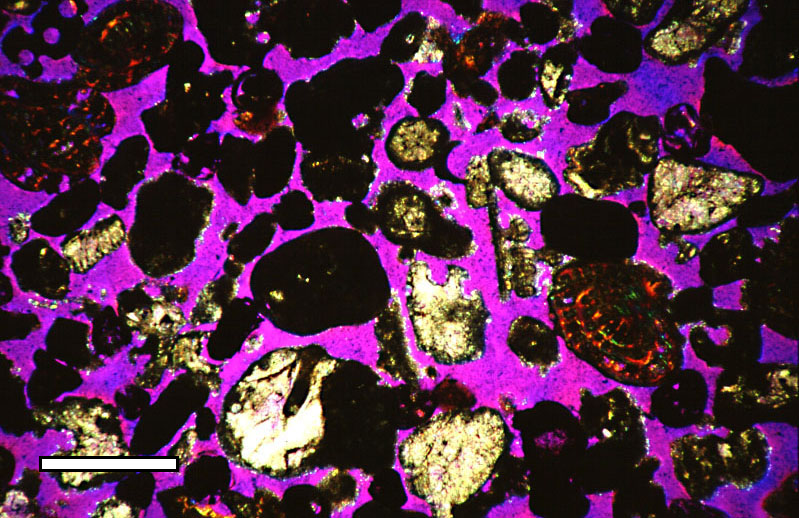

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure the "accessible void", the total amount of void space accessible from the surface (cf. closed-cell foam). There are many ways to test porosity in a substance or part, such as industrial CT scanning. The term porosity is used in multiple fields including pharmaceutics, ceramics, metallurgy, materials, manufacturing, petrophysics, hydrology, earth sciences, soil mechanics, and engineering. Void fraction in two-phase flow In gas-liquid two-phase flow, the void fraction is defined as the fraction of the flow-channel volume that is occupied by the gas phase or, alternatively, as the fraction of the cross-sectional area of the channel that is occupied by the gas phase. Void fraction usually varies from location to location in the flow ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Delamination

Delamination is a mode of failure where a material fractures into layers. A variety of materials including laminate composites and concrete can fail by delamination. Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3D printing which can fail from layer separation. Also, surface coatings such as paints and films can delaminate from the coated substrate. In laminated composites, the adhesion between layers often fails first causing the layers to separate. For example, in fiber-reinforced plastics, sheets of high strength reinforcement (e.g., carbon fiber, fiberglass) are bound together by a much weaker polymer matrix (e.g., epoxy). In particular, loads applied perpendicular to the high strength layers, and shear loads can cause the polymer matrix to fracture or the fiber reinforcement to debond from the polymer. Delamination also occurs in reinforced concrete when metal reinforcements near the surface corrode. The oxidized me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Braided Fabrics

3D braided fabrics are fabrics in which yarn runs through the braid in all three directions, formed by inter-plaiting three orthogonal sets of yarn.M, Subramanian Senthil Kannan, and Kumaravel S (2008). "A Comprehensive Look at 3-D Fabrics." The Indian Textile Journal. The fiber architecture of three-dimensional braided fabrics provides high strength, stiffness, and structural integrity, making them suitable for a wide array of applications. 3D fabrics can be produced via weaving, knitting, and non-weaving processes. History Three-dimensional braiding is among the oldest and most important of textile processes, transforming small natural fibers into more functional forms. Fabrics used in 3D braiding, such as rope, have been used since 4,000 BC. In 1748, patents for the first 3D braiding machines were initiated in England. Most 3D braiding machines of the time were developed by modifying 2D braiding machines. In 1767, the first braiding machines which produced two-dimensional fabri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Orthogonality

In mathematics, orthogonality is the generalization of the geometric notion of ''perpendicularity''. By extension, orthogonality is also used to refer to the separation of specific features of a system. The term also has specialized meanings in other fields including art and chemistry. Etymology The word comes from the Ancient Greek ('), meaning "upright", and ('), meaning "angle". The Ancient Greek (') and Classical Latin ' originally denoted a rectangle. Later, they came to mean a right triangle. In the 12th century, the post-classical Latin word ''orthogonalis'' came to mean a right angle or something related to a right angle. Mathematics Physics * In optics, polarization states are said to be orthogonal when they propagate independently of each other, as in vertical and horizontal linear polarization or right- and left-handed circular polarization. * In special relativity, a time axis determined by a rapidity of motion is hyperbolic-orthogonal to a space axis of simu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)