|

3D Microfabrication

Three-dimensional (3D) microfabrication refers to manufacturing techniques that involve the layering of materials to produce a three-dimensional structure at a microscopic scale. These structures are usually on the scale of micrometers and are popular in microelectronics and microelectromechanical systems. Rapid prototyping Much like their macroscopic analog, microstructures can be produced using rapid prototyping methods. These techniques generally involve the layering of some resin, with each layer being much thinner than that used for conventional processes in order to produce higher resolution microscopic components. Layers in processes such as electrochemical fabrication can be as thin as 5 to 10 μm. The creation of microscopic structures is similar to conventional additive manufacturing techniques in that a computer aided design model is sliced into an appropriate number of two-dimensional layers in order to create a toolpath. This toolpath is then followed by a mechanica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microelectronics

Microelectronics is a subfield of electronics. As the name suggests, microelectronics relates to the study and manufacture (or microfabrication) of very small electronic designs and components. Usually, but not always, this means micrometre-scale or smaller. These devices are typically made from semiconductor materials. Many components of normal electronic design are available in a microelectronic equivalent. These include transistors, capacitors, inductors, resistors, diodes and (naturally) insulators and conductors can all be found in microelectronic devices. Unique wiring techniques such as wire bonding are also often used in microelectronics because of the unusually small size of the components, leads and pads. This technique requires specialized equipment and is expensive. Digital integrated circuits (ICs) consist of billions of transistors, resistors, diodes, and capacitors. Analog circuits commonly contain resistors and capacitors as well. Inductors are used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microelectromechanical Systems

Microelectromechanical systems (MEMS), also written as micro-electro-mechanical systems (or microelectronic and microelectromechanical systems) and the related micromechatronics and microsystems constitute the technology of microscopic devices, particularly those with moving parts. They merge at the nanoscale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines in Japan and microsystem technology (MST) in Europe. MEMS are made up of components between 1 and 100 micrometers in size (i.e., 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e., 0.02 to 1.0 mm), although components arranged in arrays (e.g., digital micromirror devices) can be more than 1000 mm2. They usually consist of a central unit that processes data (an integrated circuit chip such as microprocessor) and several components that interact with the surroundings (such as microsensors). Because of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stereolithography

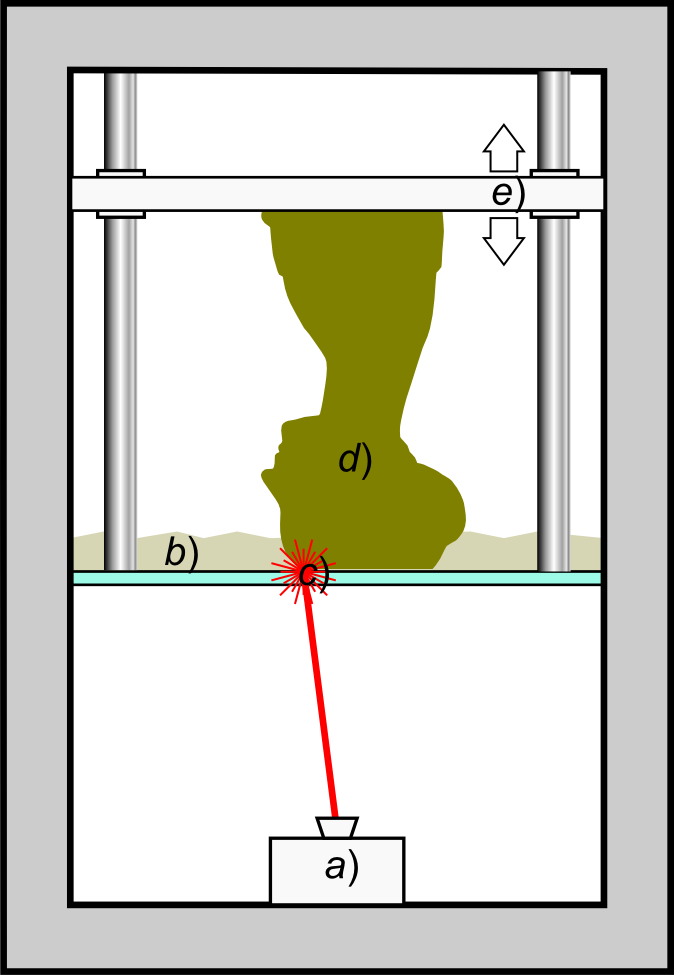

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers.U.S. Patentbr>4,575,330(“Apparatus for Production of Three-Dimensional Objects by Stereolithography”) Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive. History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fused Deposition Modeling

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or called ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use. Fused filament printing is now the most popular process ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Selective Laser Sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to selective laser melting; the two are instantiations of the same concept but differ in technical details. SLS (as well as the other mentioned AM techniques) is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves. History Selective laser sintering (SLS) was developed and patented by Dr. Carl Deckard and academic adviser, Dr. Joe Beaman at the University of Texas at Austin in the mid-1980s, under sponsorship of DARPA. Deckard and Beaman were involved in the resulting start up company DTM ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Laser Microfab

3-D, 3D, or 3d may refer to: Science, technology, and mathematics Relating to three-dimensionality * Three-dimensional space ** 3D computer graphics, computer graphics that use a three-dimensional representation of geometric data ** 3D film, a motion picture that gives the illusion of three-dimensional perception ** 3D modeling, developing a representation of any three-dimensional surface or object ** 3D printing, making a three-dimensional solid object of a shape from a digital model ** 3D display, a type of information display that conveys depth to the viewer ** 3D television, television that conveys depth perception to the viewer ** Stereoscopy, any technique capable of recording three-dimensional visual information or creating the illusion of depth in an image Other uses in science and technology or commercial products * 3D projection * 3D rendering * 3D scanning, making a digital representation of three-dimensional objects * 3D video game (other) * 3-D Secure, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multiphoton Lithography

Multiphoton lithography (also known as direct laser lithography or direct laser writing) of polymer templates has been known for years by the photonic crystal community. Similar to standard photolithography techniques, structuring is accomplished by illuminating negative-tone or positive-tone photoresists via light of a well-defined wavelength. The fundamental difference is, however, the avoidance of reticles. Instead, two-photon absorption is utilized to induce a dramatic change in the solubility of the resist for appropriate developers. Hence, multiphoton lithography is a technique for creating small features in a photosensitive material, without the use of complex optical systems or photomasks. This method relies on a multi-photon absorption process in a material that is transparent at the wavelength of the laser used for creating the pattern. By scanning and properly modulating the laser, a chemical change (usually polymerization) occurs at the focal spot of the laser and can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise impossible to construct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photopolymerisation

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many forms of polymerization and different systems exist to categorize them. In chemical compounds, polymerization can occur via a variety of reaction mechanisms that vary in complexity due to the functional groups present in the reactants and their inherent steric effects. In more straightforward polymerizations, alkenes form polymers through relatively simple radical reactions; in contrast, reactions involving substitution at a carbonyl group require more complex synthesis due to the way in which reactants polymerize. Alkanes can also be polymerized, but only with the help of strong acids. As alkenes can polymerize in somewhat straightforward radical reactions, they form useful compounds such as polyethylene and polyvinyl chloride (PVC), wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing Processes

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, therefore the numerous available 3D printing process tend to be additive in nature with a few key differences in the technologies and the materials used in this process. Some of the different types of physical transformations which are used in 3D printing include melt extrusion, light polymerization, continuous liquid interface production and sintering. Types of 3D printing processes There are many different 3D printing processes, that can be grouped into seven categories: * Vat photopolymerization * Material jetting * Binder jetting * Powder bed fusion * Material extrusion * Directed energy deposition * Sheet lamination Each process and piece of equipment has pros and cons associated with it. These usually involve aspects such as speed, costs, versatility with respect to feedstock ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)