|

1ZZ-FE

The Toyota ZZ engine family is a straight-4 piston engine series. The ZZ series uses a die-cast aluminium engine block with thin press-fit cast iron cylinder liners, and aluminium DOHC 4-valve cylinder heads. The camshafts are chain-driven. The two 1.8 L members of the family, the 1ZZ and 2ZZ, use different bore and stroke. The former was optimised for economy, with torque emphasised in lower revolutions per minute operating range, while the latter is a "square" design optimised for high-RPM torque, yielding higher peak power. The ZZ family replaced the extremely popular cast-iron block '' 4A'' engines. Toyota engine names are interpreted as follows. The leading number denotes the generation, and the next one or two letters, specify the engine family. The remaining letters, following a hyphen, describe the engine's major features. For example, the 2ZZ-GE can be decoded as being the second generation of the ZZ engine series and features a performance-oriented cylinder hea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota Corolla (E120)

The Toyota Corolla (E120/E130) is the ninth generation of compact cars sold by Toyota under the Corolla nameplate. In Japan, this series arrived to the market in August 2000; however, exports were typically not achieved until 2001 and 2002 depending on the market. The sedan and station wagon arrived first in August 2000, followed by the five-door hatchback in January 2001, and the Europe-only three-door hatchback in 2002. Toyota supplemented the original styling with an edgier, hatchback-only styling treatment from 2002. Sedans and wagons sold in Japan adopted a new front-end design in 2004, although this version did not typically reach export markets. In other Asian markets and the Americas, the ninth generation Corolla (sedan and wagon only) had unique front and rear styling treatments with mild updates over the model's production run. The E120/E130 model offered a longer wheelbase. It is built on a shortened V50 series Vista platform. From being marketed as a premium comp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

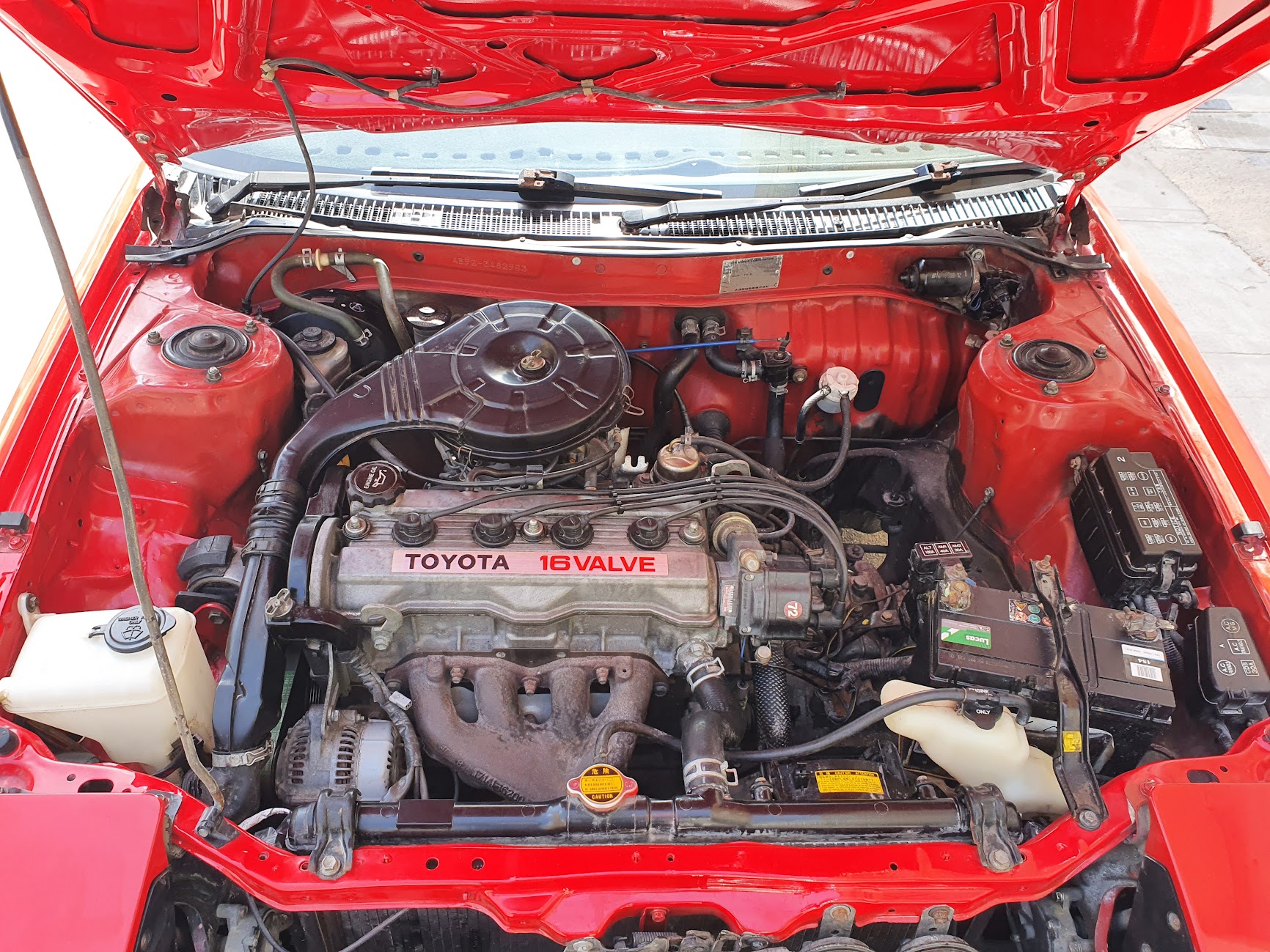

Toyota ZR Engine

The ZR engine is a family of straight-four 16-valve all-aluminum and water cooled gasoline engines with a die-cast aluminum block developed by Toyota Motor Corporation, produced from 2007. Engines displace from 1.6 to 2.0 liters. Most engines in this family are equipped with Toyota's dual VVT-i technology that optimizes both intake and exhaust valve timing. This engine family is also the first to use Toyota's Valvematic system, first appearing on the Noah and Voxy in 2007 and then the European Avensis in 2009. 1ZR-FE The Toyota 1ZR-FE is a DOHC, 16-valve, engine equipped with dual VVT-i. This engine is available with either manual gearbox (5 or 6 Speed), a "multi-mode" manual transmission (MM-T 5 Speed) or an automatic gearbox (4 Speed). This new engine is now replacing the 3ZZ-FE engine in most applications. Output for this engine is rated at at 6400 rpm and of torque at 5200 rpm net. ;Specifications: * Engine type : In-Line 4-cylinder DOHC 16-valve * Bore x ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

VVTL-i

VVT-i, or Variable Valve Timing with intelligence, is an automobile variable valve timing technology developed by Toyota. It was first introduced in 1995 with the ''Toyota JZ engine#2JZ-GE, 2JZ-GE'' engine found in the Toyota_Crown (S150), JZS155 Toyota Crown and Toyota_Crown_Majesta (S150), Crown Majesta. The VVT-i system replaces the Toyota VVT system first introduced in 1991 with the five-valve per cylinder ''Toyota A engine#4A-GE (20-valve), 4A-GE'' engine found in the Toyota Corolla Levin#AE100/101 Series (1991–1995), AE101 Corolla Levin and Toyota Sprinter Trueno#AE100/101 Series (1991–1995), Sprinter Trueno. The VVT system is a 2-stage hydraulically controlled cam phasing system. VVT-i varies the timing of the intake poppet valve, valves by adjusting the relationship between the camshaft drive (belt or chain) and intake camshaft. Engine oil pressure is applied to an actuator to adjust the camshaft position. Adjustments in the overlap time between the exhaust valve clo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota Racing Development

Toyota Racing Development (also known by its abbreviation TRD) is the in-house tuning shop for all Toyota, Lexus and formerly Scion cars. ''TRD'' is responsible both for improving street cars for more performance and supporting Toyota's racing interests around the world. TRD produces various tuning products and accessories, including performance suspension components, superchargers, and wheels. TRD parts are available through Toyota dealers, and are also available as accessories on brand-new Toyotas and Scions. Performance parts for Lexus vehicles are now labeled as ''F-Sport'' and performance Lexus models are labeled ''F'' to distinguish Lexus's F division from TRD. there are two official branches of TRD: TRD Japan (a.k.a. Toyota Technocraft) and TRD USA. Each of these branches has both a performance tuning division and a race (or competition) division. In 2018, TRD Japan and Toyota Modellista merged to form Toyota Customizing & Development Co., Ltd (TCD). TRD Japan's Race ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

VVT-i

VVT-i, or Variable Valve Timing with intelligence, is an automobile variable valve timing technology developed by Toyota. It was first introduced in 1995 with the ''2JZ-GE'' engine found in the JZS155 Toyota Crown and Crown Majesta. The VVT-i system replaces the Toyota VVT system first introduced in 1991 with the five-valve per cylinder '' 4A-GE'' engine found in the AE101 Corolla Levin and Sprinter Trueno. The VVT system is a 2-stage hydraulically controlled cam phasing system. VVT-i varies the timing of the intake valves by adjusting the relationship between the camshaft drive (belt or chain) and intake camshaft. Engine oil pressure is applied to an actuator to adjust the camshaft position. Adjustments in the overlap time between the exhaust valve closing and intake valve opening result in improved engine efficiency. Variants of the system, including VVTL-i, Dual VVT-i, VVT-iE, VVT-iW and Valvematic, have followed. VVTL-i VVTL-i (Variable Valve Timing and Lift intellig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota A Engine

The Toyota A Series engines are a family of inline-four internal combustion engines with displacement from 1.3 L to 1.8 L produced by Toyota Motor Corporation. The series has cast iron engine blocks and aluminum cylinder heads. To make the engine as short as possible, the cylinders are siamesed. The development of the series began in the late 1970s, when Toyota wanted to develop a completely new engine for the Toyota Tercel, the successor of Toyota's K engine. The goal was to achieve good fuel efficiency and performance as well as low emissions with a modern design. The A-series includes one of the first Japanese mass-production DOHC, four-valve-per-cylinder engines, the 4A-GE, and a later version of the same engine was one of the first production five-valve-per-cylinder engines. Toyota joint venture partner Tianjin FAW Xiali produces the 1.3 L 8A and resumed production of the 5A in 2007. 1A The 1.5 L 1A was produced between 1978 and 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han Dynasty in China, and they were widespread by the medieval period. The camshaft was described in 1206 by engineer Al-Jazari. He employed it as part of his automata, water-raising machines, and water clocks such as the castle clock. Once the rotative version of the steam engine was developed in the late 18th century, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chain Drive

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles. Most often, the power is conveyed by a roller chain, known as the drive chain or transmission chain, passing over a sprocket gear, with the teeth of the gear meshing with the holes in the links of the chain. The gear is turned, and this pulls the chain putting mechanical force into the system. Another type of drive chain is the Morse chain, invented by the Morse Chain Company of Ithaca, New York, United States. This has inverted teeth. Sometimes the power is output by simply rotating the chain, which can be used to lift or drag objects. In other situations, a second gear is placed and the power is recovered by attaching shafts or hubs to this gear. Though drive chains are often simple oval loops, they can also go around corners by placi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bore (engine)

In a piston engine, the bore (or cylinder bore) is the diameter of each cylinder. Engine displacement is calculated based on bore, stroke length and the number of cylinders: displacement = The stroke ratio, determined by dividing the bore by the stroke, traditionally indicated whether an engine was designed for power at high engine speeds (rpm) or torque at lower engine speeds. The term "bore" can also be applied to the bore of a locomotive cylinder or steam engine pistons. Steam locomotive The term bore also applies to the cylinder of a steam locomotive or steam engine. See also * Bore pitch * Compression ratio * Engine displacement Engine displacement is the measure of the cylinder volume swept by all of the pistons of a piston engine, excluding the combustion chambers. It is commonly used as an expression of an engine's size, and by extension as a loose indicator of the ... References {{Steam engine configurations Engine technology ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stroke (engine)

In the context of an internal combustion engine, the term stroke has the following related meanings: * A phase of the engine's cycle (e.g. compression stroke, exhaust stroke), during which the piston travels from top to bottom or vice versa. * The type of power cycle used by a piston engine (e.g. two-stroke engine, four-stroke engine). * "Stroke length", the distance travelled by the piston during each cycle. The stroke length––along with bore diameter––determines the engine's displacement. Phases in the power cycle Commonly used engine phases or strokes (i.e. those used in a four-stroke engine) are described below. Other types of engines can have very different phases. Induction-intake stroke The induction stroke is the first phase in a four-stroke (e.g. Otto cycle or Diesel cycle) engine. It involves the downward movement of the piston, creating a partial vacuum that draws a air-fuel mixture (or air alone, in the case of a direct injection engine) into the combus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of the body. The concept originated with the studies by Archimedes of the usage of levers, which is reflected in his famous quote: "''Give me a lever and a place to stand and I will move the Earth''". Just as a linear force is a push or a pull, a torque can be thought of as a twist to an object around a specific axis. Torque is defined as the product of the magnitude of the perpendicular component of the force and the distance of the line of action of a force from the point around which it is being determined. The law of conservation of energy can also be used to understand torque. The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. When being referred to as moment of force, it is commonly denoted by . In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Revolutions Per Minute

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or with the notation min−1) is a unit of rotational speed or rotational frequency for rotating machines. Standards ISO 80000-3:2019 defines a unit of rotation as the dimensionless unit equal to 1, which it refers to as a revolution, but does not define the revolution as a unit. It defines a unit of rotational frequency equal to s−1. The superseded standard ISO 80000-3:2006 did however state with reference to the unit name 'one', symbol '1', that "The special name revolution, symbol r, for this unit is widely used in specifications on rotating machines." The International System of Units (SI) does not recognize rpm as a unit, and defines the unit of frequency, Hz, as equal to s−1. :\begin 1~&\text &&=& 60~&\text \\ \frac~&\text &&=& 1~&\text \end A corresponding but distinct quantity for describing rotation is angular velocity, for which the SI unit is the ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)