|

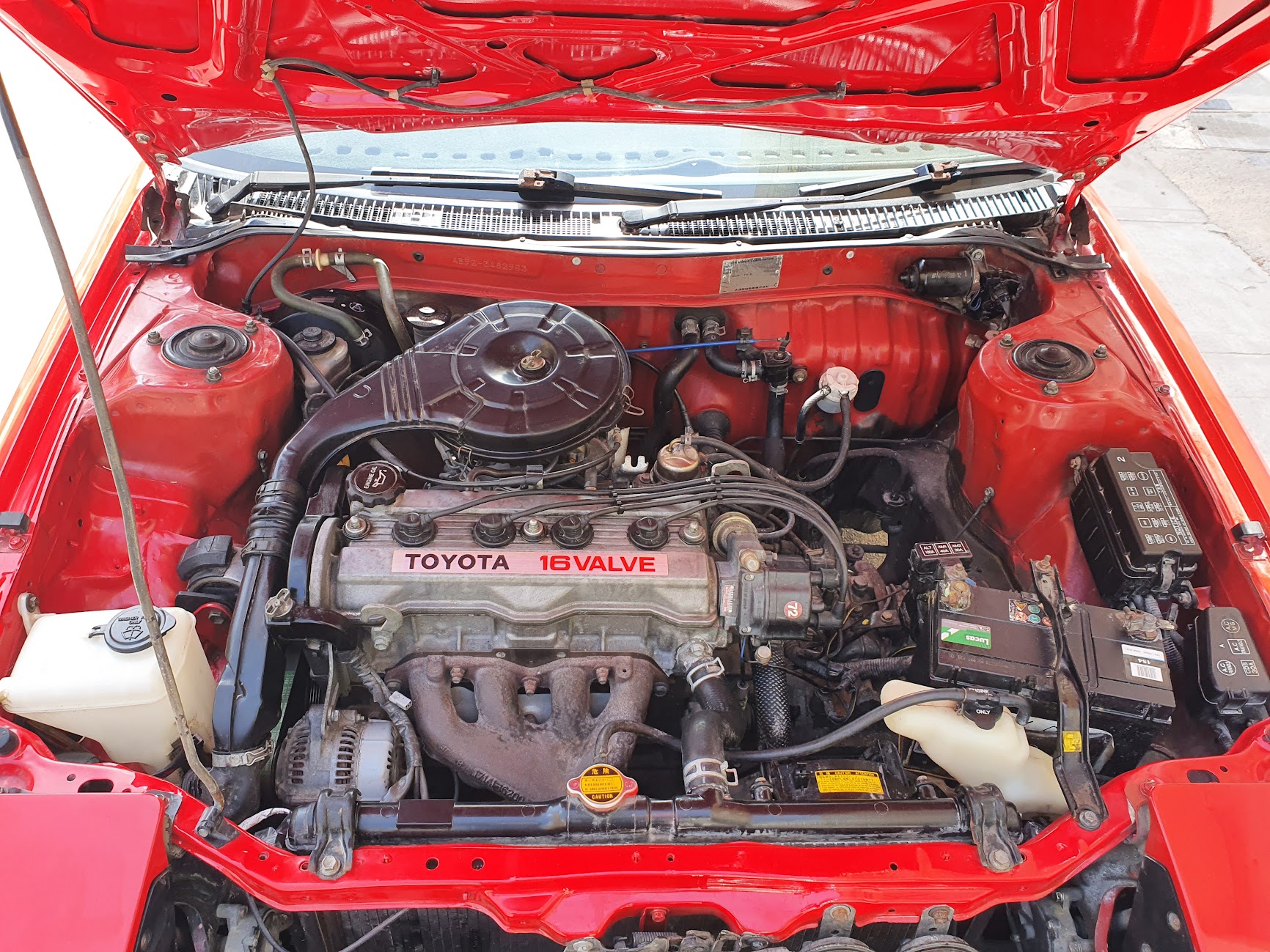

16-valve

In automotive engineering a multi-valve or multivalve engine is one where each cylinder has more than two valves. A multi-valve engine has better breathing and may be able to operate at higher revolutions per minute (RPM) than a two-valve engine, delivering more power. Multi-valve rationale Multi-valve engine design A multi-valve engine design has three, four, or five valves per cylinder to achieve improved performance. Any four-stroke internal combustion engine needs at least two valves per cylinder: one for ''intake'' of air (and often fuel), and another for ''exhaust'' of combustion gases. Adding more valves increases valve area and improves the flow of intake and exhaust gases, thereby enhancing combustion, volumetric efficiency, and power output. Multi-valve geometry allows the spark plug to be ideally located within the combustion chamber for optimal flame propagation. Multi-valve engines tend to have smaller valves that have lower reciprocating mass, which can redu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mazda B Engine

The Mazda B-series engine - not to be confused with the Mazda B-Series truck - is a small-sized, iron-block, inline four-cylinder with belt-driven SOHC and DOHC valvetrain ranging in displacement from 1.1 to 1.8 litres. It was used from front-wheel drive economy applications to the turbocharged full-time 4WD 323 GTX and rear-wheel drive Miata as well as numerous other models. The Mazda B-series is a "non-interference" design, meaning that breakage of its timing belt does not result in damage to valves or pistons, because the opening of the valves, the depth of the combustion chamber and (in some variants) the shaping of the piston crown allow sufficient clearance for the open valves in any possible piston position. B1 B1 - (68.0x78.4 mm) - came only as a SOHC 8-valve. It was available in the 1987-1989 Mazda 121 and later model Kia Sephia in European and Asian markets. A fuel-injected variant was used in select European market 1991-1995 Mazda 121s BJ The BJ engine (7 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota A Engine

The Toyota A Series engines are a family of inline-four internal combustion engines with displacement from 1.3 L to 1.8 L produced by Toyota Motor Corporation. The series has cast iron engine blocks and aluminum cylinder heads. To make the engine as short as possible, the cylinders are siamesed. The development of the series began in the late 1970s, when Toyota wanted to develop a completely new engine for the Toyota Tercel, the successor of Toyota's K engine. The goal was to achieve good fuel efficiency and performance as well as low emissions with a modern design. The A-series includes one of the first Japanese mass-production DOHC, four-valve-per-cylinder engines, the 4A-GE, and a later version of the same engine was one of the first production five-valve-per-cylinder engines. Toyota joint venture partner Tianjin FAW Xiali produces the 1.3 L 8A and resumed production of the 5A in 2007. 1A The 1.5 L 1A was produced between 1978 and 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SOHC

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an OHV en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Volkswagen Group Petrol Engines

The spark-ignition petrol engines listed below operate on the four-stroke cycle, and unless stated otherwise, use a wet sump lubrication system, and are water-cooled.ETKA official factory data Since the Volkswagen Group is German, official internal combustion engine performance ratings are published using the International System of Units (commonly abbreviated "SI"), a modern form of the metric system of figures. Motor vehicle engines will have been tested by a Deutsches Institut für Normung (DIN) accredited testing facility, to either the original '' 80/1269/EEC'', or the later ''1999/99/ EC'' standards. The standard initial measuring unit for establishing the rated motive power output is the kilowatt (kW); and in their official literature, the power rating may be published in either the kW, or the metric horsepower (often abbreviated "PS" for the German word ''Pferdestärke''), or both, and may also include conversions to imperial units such as the horsepower (hp) or bra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nissan VQ35DE 005

, trading as Nissan Motor Corporation and often shortened to Nissan, is a Japanese multinational automobile manufacturer headquartered in Nishi-ku, Yokohama, Japan. The company sells its vehicles under the Nissan, Infiniti, and Datsun brands, with in-house performance tuning products (including cars) labelled Nismo. The company traces back to the beginnings of the 20th century, with the Nissan ''zaibatsu'', now called Nissan Group. Since 1999, Nissan has been part of the Renault–Nissan–Mitsubishi Alliance (Mitsubishi joining in 2016), a partnership between Nissan and Mitsubishi Motors of Japan, with Renault of France. , Renault holds a 43.4% voting stake in Nissan, while Nissan holds a 15% non-voting stake in Renault. Since October 2016 Nissan has held a 34% controlling stake in Mitsubishi Motors. In 2013, Nissan was the sixth largest automaker in the world, after Toyota, General Motors, Volkswagen Group, Hyundai Motor Group, and Ford. In 2014, Nissan was the largest ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yamaha Genesis Engine

"Genesis" is Yamaha's marketing name for a range of innovative high performance multi-valve motorcycle engines. The flexible design of the engine allowed Yamaha to use it on a variety of configurations, from sport bikes to outboard engines. The five-valve engine The DOHC Genesis engine has five valves per cylinder and downdraft carburetors. Yamaha adopted the 5-valve concept, using three intake valves and two exhaust valves per cylinder, because it allowed both excellent volumetric efficiency and high rpm. As designers began to appreciate the benefits of multi-valve layout, 4-valves-per-cylinder (and even 3-valves) became common. In a multivalve engine, maximum rpm is limited by the size of the largest valves: in a 3-valver, the exhaust valve is larger, and in a 4-valver, the inlet valves are larger. The significance of the five-valve engine compared to other multivalve configurations engines is that (like a 3-valver) there were more intake valves than exhaust ones; yet all valv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head Porting

Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve their air flow. Cylinder heads, as manufactured, are usually suboptimal for racing applications due to being designed for maximum durability. Ports can be modified for maximum power, minimum fuel consumption, or a combination of the two, and the power delivery characteristics can be changed to suit a particular application. Dealing with air Daily human experience with air gives the impression that air is light and nearly non-existent as we move slowly through it. However, an engine running at high speed experiences a totally different substance. In that context, air can be thought of as thick, sticky, elastic, gooey and heavy (see viscosity), and head porting helps to alleviate this. Port modifications When a modification is decided upon through testing with an air flow bench, the original port wall material can be reshaped by hand with die grinde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Valve

A rotary valve (also called rotary-motion valve) is a type of valve in which the rotation of a passage or passages in a transverse plug regulates the flow of liquid or gas through the attached pipes. The common stopcock is the simplest form of rotary valve. Rotary valves have been applied in numerous applications, including: * Changing the pitch of brass instruments. * Controlling the steam and exhaust ports of steam engines, most notably in the Corliss steam engine. * Periodically reversing the flow of air and fuel across the open hearth furnace. * Loading sample on chromatography columns. * Certain types of two-stroke and four-stroke engines. * Most hydraulic automotive power steering control valves. Use in brass instruments In the context of brass instruments, rotary valves are found on horns, trumpets, trombones, flugelhorns, and tubas. The cornet derived from the posthorn, by applying rotary valves to it in the 1820s in France. An alternative to a rotary valve trumpet wou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable-length Intake Manifold

In internal combustion engines, a variable-length intake manifold (VLIM),variable intake manifold (VIM), or variable intake system (VIS) is an automobile internal combustion engine manifold technology. As the name implies, VLIM/VIM/VIS can vary the length of the intake tract - in order to optimise power and torque across the range of engine speed operation, as well as help provide better fuel efficiency. This effect is often achieved by having two separate intake ports, each controlled by a valve, that open two different manifolds - one with a short path that operates at full engine load, and another with a significantly longer path that operates at lower load. The first patent issued for a variable length intake manifold was published in 1958, US Patent US2835235 by Daimler Benz AG. There are two main effects of variable intake geometry: ;Swirl: Variable geometry can create a beneficial air swirl pattern, or turbulence in the combustion chamber. The swirling helps distribute th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Valve Timing

In internal combustion engines, variable valve timing (VVT) is the process of altering the timing of a valve lift event, and is often used to improve performance, fuel economy or emissions. It is increasingly being used in combination with variable valve lift systems. There are many ways in which this can be achieved, ranging from mechanical devices to electro-hydraulic and camless systems. Increasingly strict emissions regulations are causing many automotive manufacturers to use VVT systems. Two-stroke engines use a power valve system to get similar results to VVT. Background theory The valves within an internal combustion engine are used to control the flow of the intake and exhaust gases into and out of the combustion chamber. The timing, duration and lift of these valve events has a significant impact on engine performance. Without variable valve timing or variable valve lift, the valve timing is the same for all engine speeds and conditions, therefore compromises are neces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supercharger

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a supercharger is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gasses. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and/or increase power outputs. Des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharging

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |